In today’s competitive manufacturing landscape, CNC (Computer Numerical Control) machining has become essential for creating precise parts across various industries, including aerospace, automotive, and tooling. Among the many machining methods, 3-axis and 5-axis machining are two of the most commonly utilized. Choosing the right method can significantly impact production quality, efficiency, and cost. But how do you know whether 3-axis or 5-axis machining is the best fit for your project? This article explores the differences between these two machining techniques to help you make an informed choice.

Understanding 3-Axis Machining

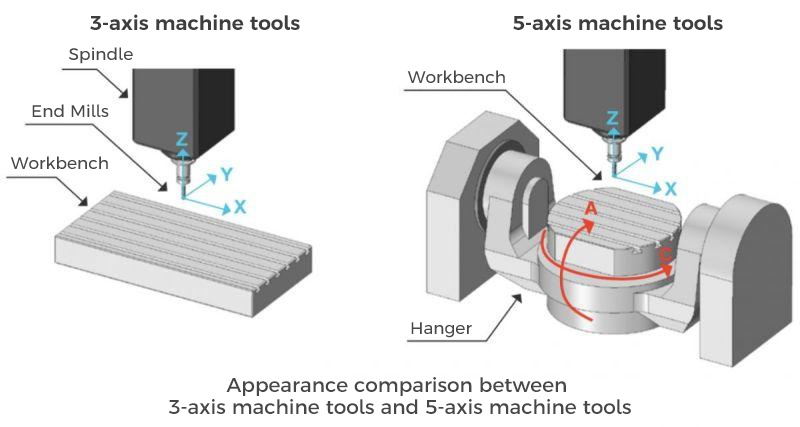

3-axis machining is the most traditional and commonly used form of CNC machining. It utilizes three primary axes—X, Y, and Z—to guide the tool’s movement, meaning the tool can only move along these three linear axes. This setup is ideal for creating parts with flat surfaces, slots, and other relatively simple geometries, as well as basic 3D shapes.

Advantages of 3-Axis Machining

1. Cost-Effective: The simplicity of 3-axis machines makes them generally more affordable to purchase and maintain than 5-axis machines, making them a cost-effective solution for many small to medium-sized manufacturers.

2. Ease of Operation: Since 3-axis machining only requires basic programming, operators and machinists can master it more quickly than 5-axis. This can lead to lower labor costs and quicker turnaround times.

3. Stability and Accuracy for Simple Shapes: Due to the reduced complexity of movement, 3-axis machines are inherently stable and well-suited for producing consistent and accurate parts with simpler geometries.

Limitations of 3-Axis Machining

While 3-axis machining is versatile, it does have its limitations. The main drawback is that it’s restricted to movement along three axes, which makes it unsuitable for more complex parts with intricate curves, multiple surfaces, or angled cuts. For such parts, the tool cannot reach certain surfaces without repositioning the part, resulting in potential alignment issues or additional labor and time costs.

Understanding 5-Axis Machining

5-axis machining builds on the capabilities of 3-axis machining by adding two rotational axes, typically known as the A and C axes. This means that the cutting tool can approach the workpiece from virtually any angle, making it ideal for complex shapes, multi-surface parts, and high-precision machining. 5-axis machining has become the gold standard for industries that require intricate parts with tight tolerances, such as aerospace and medical device manufacturing.

Advantages of 5-Axis Machining

1. Enhanced Flexibility and Reach: The ability to maneuver the cutting tool from multiple angles allows for the creation of intricate shapes, deep cavities, and curved surfaces that would be impossible to achieve with 3-axis machining alone.

2. Increased Accuracy Through Reduced Repositioning: 5-axis machines can often complete a part in a single setup, reducing the need to reposition or re-clamp the part. This minimizes the risk of alignment errors and increases the overall precision of the final product.

3. Higher Efficiency: The ability to complete complex parts in fewer setups means that 5-axis machining can reduce cycle times, leading to faster production and higher output—a critical advantage for industries with demanding production schedules.

In order to give our customers better quality and service, Yixin Precision purchased 3 sets of 5-axis machining center equipment around 2024, which effectively improved the production efficiency and machining precision.

Limitations of 5-Axis Machining

The main limitation of 5-axis machining is its higher cost. Both the equipment itself and the maintenance required are more expensive than 3-axis machines. Additionally, programming a 5-axis machine is far more complex, requiring skilled operators and specialized software. This adds to the setup time, labor costs, and production planning requirements, which can be a drawback for smaller companies or simpler jobs.

Key Differences Between 3-Axis and 5-Axis Machining

1. Degree of Movement: The most obvious difference is the range of motion. In 3-axis machining, the tool can only move linearly along the X, Y, and Z axes, while in 5-axis machining, the tool has an additional two rotational axes, allowing for multi-angle access to the workpiece.

2. Application and Complexity: 3-axis machining is suitable for simpler shapes and surfaces, making it ideal for flat or shallow parts. In contrast, 5-axis machining is preferred for complex geometries that require multiple angles, such as turbine blades or medical implants.

3. Precision and Quality: 5-axis machining can significantly reduce the need for re-clamping, leading to higher accuracy and consistency, which is especially crucial in industries where precision is critical. 3-axis machining, while precise, may require multiple setups for complex parts, which can introduce slight variances.

4. Cost and Setup Time: 3-axis machines are typically more affordable and have a shorter learning curve, which makes them a popular choice for simpler parts and smaller-scale production. 5-axis machines, however, are more expensive and require advanced programming, leading to higher setup and operational costs.

How to Choose Between 3-Axis and 5-Axis Machining?

Selecting the best machining process requires evaluating your specific requirements, including the complexity of the part, the precision needed, the budget, and the desired production speed. Here are some guidelines to help you decide:

1. Evaluate Part Geometry: For parts with simple, flat surfaces or basic 3D shapes, 3-axis machining will often suffice. However, for components with complex curves, deep cavities, or multi-angled surfaces, 5-axis machining is likely the better choice.

2. Precision Requirements: If the part requires high accuracy and consistency, such as aerospace or medical device components, 5-axis machining is ideal due to its ability to complete the part in a single setup. If precision requirements are moderate, 3-axis machining can still deliver high-quality results at a lower cost.

3. Production Volume and Cost Efficiency: If you’re producing high volumes of simple parts, 3-axis machining will be more cost-effective and efficient. For low to medium volume production of complex parts, the increased setup efficiency and reduced labor of 5-axis machining may justify the higher upfront cost.

4. Budget Considerations: 3-axis machines are generally less expensive to purchase, operate, and maintain, making them suitable for smaller companies or projects with limited budgets. 5-axis machines require a higher investment but provide greater flexibility, which can offset the cost in industries that require a wide variety of complex parts.

5. Time and Efficiency Needs: 5-axis machining is faster for complex parts due to its ability to complete the workpiece in one setup, reducing the need for multiple repositioning steps. This efficiency can make a big difference in industries that prioritize fast production times.

Summary

3-axis and 5-axis machining each offer distinct advantages depending on the application. In summary:

3-axis machining is cost-effective and suitable for simpler shapes, moderate precision requirements, and high-volume production of basic parts. It is an excellent choice for manufacturers who prioritize cost savings and efficient production.

5-axis machining excels in flexibility, precision, and efficiency for complex geometries, allowing for multi-surface machining and minimal repositioning. This makes it the preferred choice for industries that require complex, high-precision parts, despite the higher upfront cost.

Choosing between 3-axis and 5-axis machining ultimately depends on the complexity and accuracy required for your part, the production volume, and your budget. By assessing these factors carefully, manufacturers can optimize production processes, reduce costs, and improve product quality—ensuring they’re well-equipped to meet today’s stringent manufacturing demands.

Comments on “5-Axis vs. 3-Axis Machining: 3-Axis or 5-Axis? Choose the Right Machining Method!”